ED160BR Blade Runner - Kobelco Excavators

Product Overview

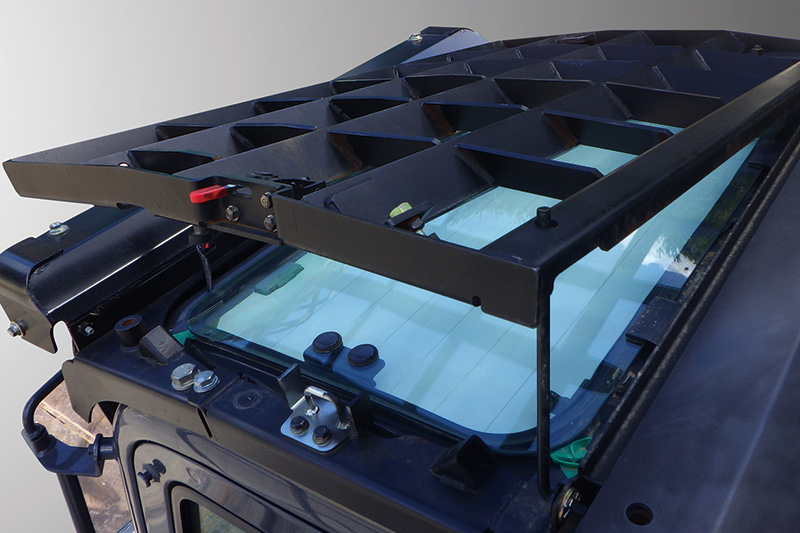

Kobelco ED160BR Blade Runner Excavator – a versatile excavator. Features a six-way dozer blade that offers power, angle, and tilt capability. Easy for pushing material out of the way or quickly refilling a work site. As one of our most fuel-efficient machines, the Kobelco ED160BR Blade Runner Excavator features the exclusive Kobelco iNDr Cooling System that reduces dust while delivering ultra-quiet operation. Multiple operating modes allow you to dial in the perfect balance of performance and fuel economy. And adjustable presets for the bucket, breaker, nibbler and thumb, allows you to change tools quickly and easily.

*This Kobelco machine’s a winner of the 2021 EquipmentWatch Lowest Cost of Ownership Award.*

Compare Models

| Model | Operating Weight | Dig Depth |

|---|---|---|

| SK130LC | 32,800 lb (14,900 kg) | 19 ft 7 in (5,980 mm) |

| SK140SRLC | 32,800 lb (14,900 kg) - Standard 33,700 lb (15,300 kg) - Offset Boom | 19 ft 7 in (5,980 mm) - Standard 17 ft 2 in (5,220 mm) - Offset Boom |

| ED160BR Blade Runner | 37,000 lb (16,800 kg) | 19 ft (5,790 mm) |

| SK170LC | 39,500 lb (17,900 kg) | 21 ft 3 in (6,490 mm) |

| SK230SRLC | 56,400 lb (25,600 kg) | 21 ft 7 in (6,580 mm) |

| SK270SRLC | 60,000 lb (27,200 kg) | 21 ft 9 in (6,650 mm) |

| SK210LC | 50,000 lb (22,700 kg) | 22 ft (6,700 mm) |

| SK260LC | 59,300 lb (26,900 kg) | 23 ft (7,000 mm) |

| SK300LC | 68,800 lb (31,200 kg) | 23 ft 7 in (7,200 mm) |

| SK350LC | 83,300 lb (37,800 kg) | 24 ft 10 in (7,560 mm) |

| SK390LC | 83,600 lb (37,900 kg) | 23 ft 1 in (7,040 mm) |

| SK500LC | 114,000 lb (51,700 kg) | 25 ft 7 in (7,810 mm) |

| SK850LC | 84,200 lb (38,200 kg) | 24 ft 1 in (7,350 mm) |

Find your closest McCann location!

At McCann, our mission is 'Serving the Constructor' with the supplies, equipment, and support to get the job done. From our ten regional locations throughout northern Illinois, northern Indiana and western Michigan we represent more than 400 suppliers and manufacturers as well as provide parts, service, repair and rentals.

Learn More